Division

Eco-Mobility Division Global leader of Rolling Components Industry

Technology

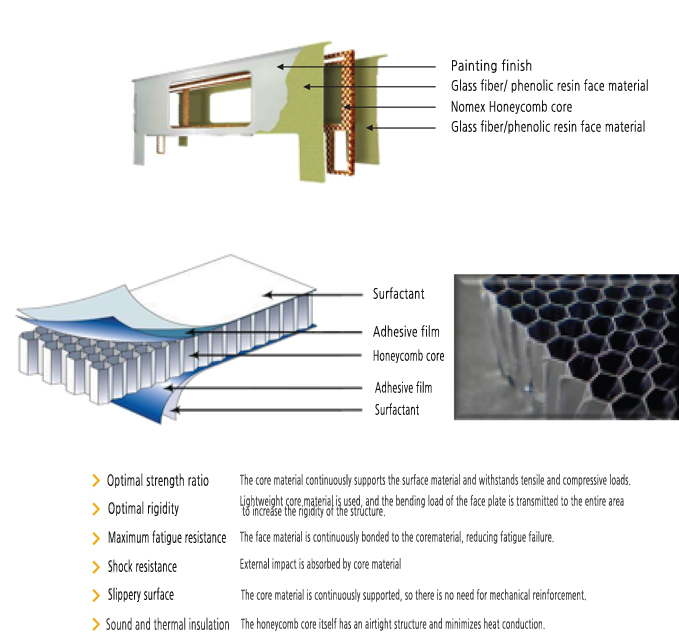

Honeycomb Sandwich Panel

We utilize glass fibers produced in our own electric direct-fusion plant, developed with proprietary technology, to create lightweight, durable interior and exterior materials for railway vehicles. Our products are in line with the railway industry's trend toward high speed and reduced vehicle maintenance costs, and feature non-combustible, lightweight composite materials that can be molded into complex shapes. Our glass/phenol honeycomb sandwich panel is flame-resistant and emits little smoke or toxic gas. It offers many advantages, including excellent durability, impact resistance, bending stiffness, and an attractive appearance. Our glass prepreg is impregnated with resin to create a viscous material that can bond chemically with the nomex honeycomb core at a temperature of approximately 135°C, eliminating the need for special adhesives. As we expand into Europe, the center of the advanced rail transportation market, and into India and Asia, we aim to become the world's leading composite material-based railroad vehicle parts company.

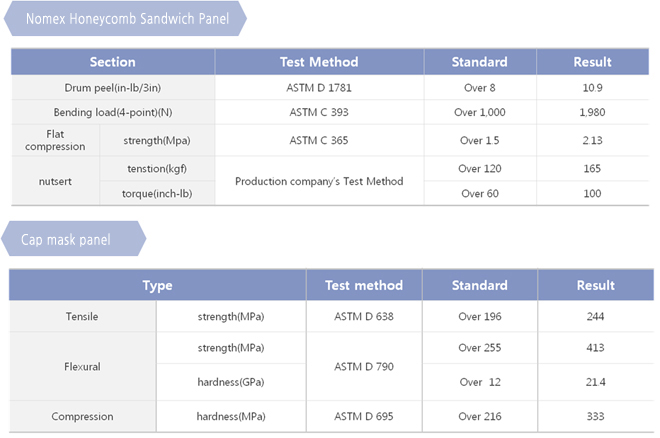

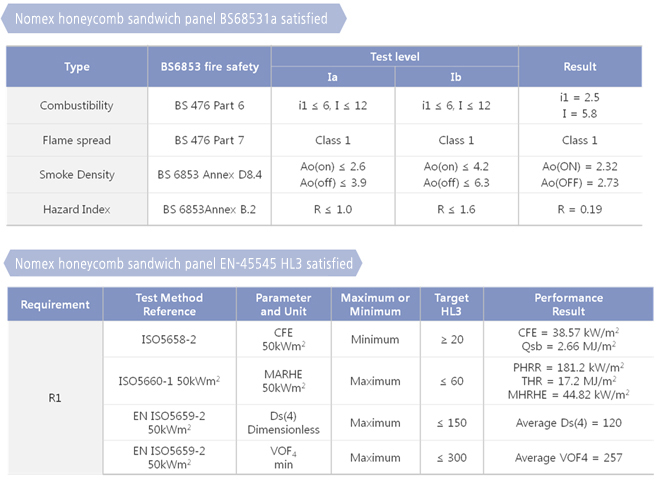

Quality status

Fire performance

Mechanical properties